Georgia Southern University Georgia Southern University

Digital Commons@Georgia Southern Digital Commons@Georgia Southern

16th Proceedings (Dresden, Germany- 2023) Progress in Material Handling Research

Summer 6-21-2023

Warehouse robotization with Wheel.me genius: A puzzle-based Warehouse robotization with Wheel.me genius: A puzzle-based

movable racks system movable racks system

Fabio Sgarbossa

Norwegian University of Science and Technology

Martin Amaral Halseide

Wheel.me

, mar[email protected]

Atle Timenes

wheel.me

Follow this and additional works at: https://digitalcommons.georgiasouthern.edu/pmhr_2023

Recommended Citation Recommended Citation

Sgarbossa, Fabio; Halseide, Martin Amaral; and Timenes, Atle, "Warehouse robotization with Wheel.me

genius: A puzzle-based movable racks system" (2023).

16th Proceedings (Dresden, Germany- 2023)

. 11.

https://digitalcommons.georgiasouthern.edu/pmhr_2023/11

This research paper is brought to you for free and open access by the Progress in Material Handling Research at

Digital Commons@Georgia Southern. It has been accepted for inclusion in 16th Proceedings (Dresden, Germany-

2023) by an authorized administrator of Digital Commons@Georgia Southern. For more information, please contact

XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEE

Warehouse robotization with wheel.me Genius: A

puzzle-based movable racks system

Fabio Sgarbossa

Department of Mechanical and Industrial

Engineering

Norwegian University of Science and

Technology

Trondheim, Norway

Abstract—In this paper, we first introduce a new type of

warehouse which combines the properties and operations of

puzzle-based storage systems and robotic mobile fulfillment.

Thanks to a long-term collaboration between the Logistics 4.0 Lab

at NTNU and wheel.me, we have introduced and explored a new

configuration called Puzzle-Based Movable Rack (PBMR) system

where racks can be moved with autonomous wheels. One

additional advantage of such system is that movable racks can

move diagonally. We model and analyze the system studying

different configurations and showing the impact on density and

average cycle time/throughput. We finally introduce potential

future research for such system.

Keywords—warehouse robotization, movable racks, analytical

model, simulation, wheel.me

I. INTRODUCTION

Online retailing experienced an acceleration in popularity

during the COVID-19 pandemic. E-commerce activities and

online retailing had already seen a steady increase in popularity,

leading to new development in warehousing technologies

suitable for the e-commerce environments [1]. Recent years’

growth in e-commerce has motivated innovation and

implementation of highly compact storage systems as in puzzle-

based storage (PBS) systems and of highly performant ones as

robotic mobile fulfillment (RMF) systems.

PBS systems are part-to-picker systems inspired by the

famous game 15-puzzle, where the objective is to arrange 15

numbered tiles in a 4×4 grid in sequence by sliding tiles into

only one empty slot. An analogous part-to-picker storage system

was proposed by [2], where the tiles resemble totes, pallets,

containers, or other stored units. With n cells in the grid, Gue

and Kim (2007) show that a puzzle-based storage system could

theoretically reach a density of (n − 1)/n, that is, leaving only

one slot (termed escort) free of stored units and achieving an

extremely high density compared to other systems. On the other

hand, the throughput capacity is relatively limited since to bring

a requested load to the I/O-location, the system must move loads

such that an escort is positioned where it can bring the requested

item closer to the I/O-location.

An RMF system is a part-to-picker system where

autonomous mobile robots (AMRs) bring storage racks to

workstations where human workers either pick requested orders

or replenish items into the storage system. An RMF system has

a storage area with aisles and sometimes also cross aisles. An

unloaded robot, i.e., a robot not carrying a storage rack, can

travel underneath the storage racks. However, a loaded robot

must use the aisles or cross aisles to transport the rack to the

workstations. With robots carrying storage racks to

workstations, [3] claim that pick rates can reach between 200

and 300 order lines per picker per hour. The great potential in

throughput capacity and performance has made RMF systems

adopted mainly in environments with small order volumes and

a large number of small stock-keeping units (SKUs). RMF

systems has also been shown to be suited for handling strong

demand fluctuations, which is characteristic for e-commerce

warehouses [1].

In their review of robotized and automated warehouse

systems, [4] categorizes PBS and RMF systems in two separate

branches of automated picking systems. These are grid-based

dynamic storage systems and moveable rack systems,

respectively. Research about PBS systems has been aimed at

reducing retrieval times while maintaining storage density

towards the absolute upper limits. RMF systems have been less

concerned with achieving very high densities, but in return,

achieve very high picking rates and throughput capacity. RMF

system’s high performance in terms of very high responsiveness

and ability to complete orders quickly has made them primarily

adopted in e-commerce sector. However, according to the

survey by [1], PBS systems were not considered to be able to

handle the tight delivery schedules in an e-commerce

environment. They argue that the movement constraints in the

system limit low enough retrieval times expected by applicable

storage and retrieval systems. However, minimizing consumed

area in warehousing by designing storage systems with higher

densities is a prevalent topic because, naturally, this can reduce

costs. The trade-off between storage density and throughput

capacity is what we seek to improve in this work.

We will link these two branches of automated picking

systems to improve the trade-off between storage density and

throughput capacity. To the best of the author’s knowledge, no

large-scale PBS system with moveable racks has been

investigated. There are good reasons why this has not been

investigated [5]. With current RMF system technology, moving

racks similarly to the proposed puzzle-based approaches in

literature for large enough systems could be unfeasible. [6]

optimize matching AMRs to storage racks in an RMF system by

modeling the problem as a traveling salesperson problem. This

problem is known to be NP-hard. The required number of AMRs

needed to puzzle racks to clear the way for the requested racks

would likely be very high, thus making this a very complex task.

Furthermore, a case study by [7] highlights the increasing

likelihood of conflicts between unloaded AMRs when the

number of AMRs increases. Devising routes for the AMRs to

move racks according to the algorithm responsible for the

puzzle-based retrieval while considering both robot scheduling

and collision avoidance could be a very challenging task indeed.

Recently, the Norwegian company wheel.me has developed

autonomous wheels. Autonomous wheels can replace regular

wheels on trolleys, carts or mounted to many other objects like

racks and pallets. They consist of computational and

mechatronic mechanisms allowing the wheels to sense the

environment, avoid collisions and drive autonomously in any

direction. Control of the wheels is done through a cloud

computing system, which can enable the coordination of

multiple objects mounted with autonomous wheels. By

mounting autonomous wheels to an object, the object can move

independently and autonomously. Autonomous wheels can be

an alternative to existing material handling equipment such as

AMRs, automated guided vehicles (AGVs), shuttles, and

conveyor belts.

Mounting autonomous wheels to storage racks removes the

need for AMRs to move racks, so in this work thanks to a long-

term collaboration between the Logistics 4.0 Lab at NTNU and

wheel.me, we have introduced and explored a new configuration

of PBS and RMF systems where we assume that loads can be

moved with autonomous wheels, extending the term loads to

include storage racks. In this way we can obtain a system with

high storage density and high throughput capacity, that we will

call Puzzle-Based Movable Rack (PBMR) system. An

illustration can be seen in Figure 1 below.

Mounting autonomous wheels to storage racks eliminates

the complexity mentioned above associated with matching

AMRs with racks and collision avoidance between unloaded

AMRs. We will assume that racks can move autonomously and

independently, thus assuming a PBMR system, where “load” is

the storage racks that can move autonomously with autonomous

wheels. Autonomous wheels also reduce constraints associated

with movement in PBS systems. Previous research in PBS

systems has mainly assumed that loads are moved with shuttles

or unit-sized conveyor belts. Under this assumption, loads have

only moved rectilinearly (i.e., in either of the four cardinal

directions) [5]. With autonomous wheels, loads can move in any

direction. Seminal research by [8] shows that travel distances

can be reduced with diagonal cross aisles in traditional aisle-

based warehouses. In our configurations, movable racks can

move also in diagonal direction.

Lastly, recent investigations of operational planning in PBS

systems indicate that retrieval time can be reduced by relaxing

constraints imposed by the original configuration [5]. By

increasing the number of escorts, it is possible to create virtual

aisles [9] allowing requested loads to move uninterruptedly. [10]

has shown through formulating an algorithm that enabled

escorts to be moved simultaneously that retrieval times could be

reduced. The term PBS system also suggests a difficult puzzle is

associated with retrieving loads. Indeed, several recent papers

propose clever algorithms for minimizing retrieval times given

constraints of the system and point to increased complexity

when the state space gets large. However, instead of taking an

operational planning perspective to solve the “puzzle” as it is, a

design optimization perspective might enable us to “cheat” the

puzzle. If it is possible to design a configuration where loads can

move diagonally to reduce travel distance and clever movement

to reduce retrieval time, there should be potential for increased

throughput capacity in a PBMR system.

Figure 1: wheel.me Genius and its installations on a movable rack.

This intersection of research topics, namely in PBS systems,

RMF systems, and non-conventional cross aisles, shapes this

work’s perspective. Description of concepts and modeling is

primarily similar to papers in the PBS research field. However,

conversely to the PBS research field, we consider density as a

result of the system configuration instead of a parameter for

operations planning and control. This perspective enables

considerably less constrained research and modeling process. It

also allows us to investigate how diagonal movement can be

utilized in a grid-based system. Most importantly, although we

do not concentrate this work on the upper limits of storage

density, we seek to find a trade-off between throughput capacity

and density, where throughput capacity can be increased from

typical PBS systems and maybe challenge RMF systems, but

with a density close to the typical PBS systems.

Specifically, we will investigate how low average cycle time

with high density can be achieved in a puzzle-based storage

system when we assume that loads can be moved with

autonomous wheels. We consider average cycle time to be the

average time needed to perform all necessary movements, which

enable a single load to be retrieved from, and a single load to be

replenished into the system. Lower average cycle time implies

higher throughput capacity for the overall system.

We divide the problem of achieving low average cycle times

into two sub-problems. First, how can we reduce average travel

distance in the system, and how can a configuration and

movement policy enable a shorter average travel distance and

movement with relaxed constraints? Travel distance is the 2-

dimensional Euclidean distance which a requested load travels

from its initially stored location to an I/O-location. The

configuration is the distribution of loads (or analogously,

escorts) according to the grid dimensions. By movement policy,

we mean the specification for performing all the necessary

movement of stored loads that enable a single load to be

retrieved from and replenished into the system.

This work seeks to meet the following objectives:

• O1. Define a travel route where loads can move diagonally

in a grid.

• O2. Design a configuration and movement policy which

retrieves requested loads along the specified travel route.

• O3. Estimate performance of a PBMR system which uses

the proposed configuration and movement policy.

This work has applied analytical modelling and simulation

approach to model a PBMR system. A program was built from

scratch as a tool to visualize and animate different

configurations and movement policies and conduct the

experiments. Furthermore, the program enabled us to assess the

feasibility of the configuration and movement policy by

simulating a large number of different cases. Given the

configuration and movement policy, we formulated an

analytical model to estimate the performance of a broader range

of scenarios than what could practically be done by the

simulation model. The analytical model has been validated

through the simulation model and both used to estimate the

performance and describe the characteristics of the

configuration and movement policy. Finally, by using the

analytical model we could compare different configurations of

the system and reflect on them for future research.

The main contributions of this work are:

1 A puzzle-based moveable rack (PBMR) system with

autonomous wheels is proposed.

2 This work is the first to propose a configuration that

enables diagonal movement that can save travel

distance up to 18.7% compared to the orthogonal (or

Manhattan) distances.

3 We combine simultaneous movement and block moves

with virtual aisles in a configuration and movement

policy that enables the requested load to be retrieved

uninterruptedly. As a result, the configuration and

movement policy can achieve an average cycle time

that is practically only dependent on average travel

distance and not constrained by the movement of non-

requested loads.

II. ANALYTICAL MODELLING AND SIMULATION

We use the following assumptions in order to model the

operation of the PBMR and so estimated the travel distance and

the travel time.

We assume that loads in the system are moved with

autonomous wheels, and the autonomous wheels operate

without errors. As mentioned, with this assumption, we expand

the term “loads” to also encapsulate storage racks in addition to

totes, pallets, containers, and other units previously

encapsulated by this term in the literature about PBS systems.

Although movement with autonomous wheels is not constrained

to a physical grid such as movement with shuttles or unit-sized

conveyor belts, we use an imaginary grid to model layout design

and behavior. This choice implies that layout design and

behavior will be similar and use many of the same theoretical

concepts as PBS systems.

Each load resemble one storage rack which can move with

autonomous wheels (1 m/s). Time required to change direction

is neglected. The storage area is modelled as a discrete grid with

cell dimensions of 1m x 1m. An escort move changes the

location of an escort from its initial cell to a new cell by moving

the load(s) between the two locations. Each moved load is a

consequence of an escort move. From each cell, a load can be

moved to either of its eight adjacent cells. A load can move to

either of the four adjacent cells in the same row or column, or it

can move to either of the four adjacent cells in the diagonal

directions. Loads are requested from a uniform distribution.

Single command operations, commonly termed single load

retrieval in PBS systems literature.

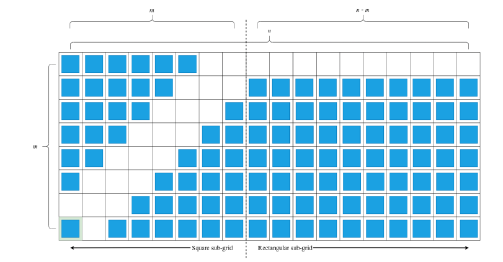

Each shape can be modelled with square and a rectangular

sub-grids (Fig. 2). The operations in the square and rectangular

sub-grids were implemented in an object oriented program

written in Python 3.6 in order to validate the results of the

analytical model. m and n are the two side of the grid. Where (m,

m) are the dimensions of the square sub-grid, and (m, n-m) are

the dimensions of the rectangular sub-grid.

Figure 2: A rectangular grid divided into a square and a rectangular sub-grid

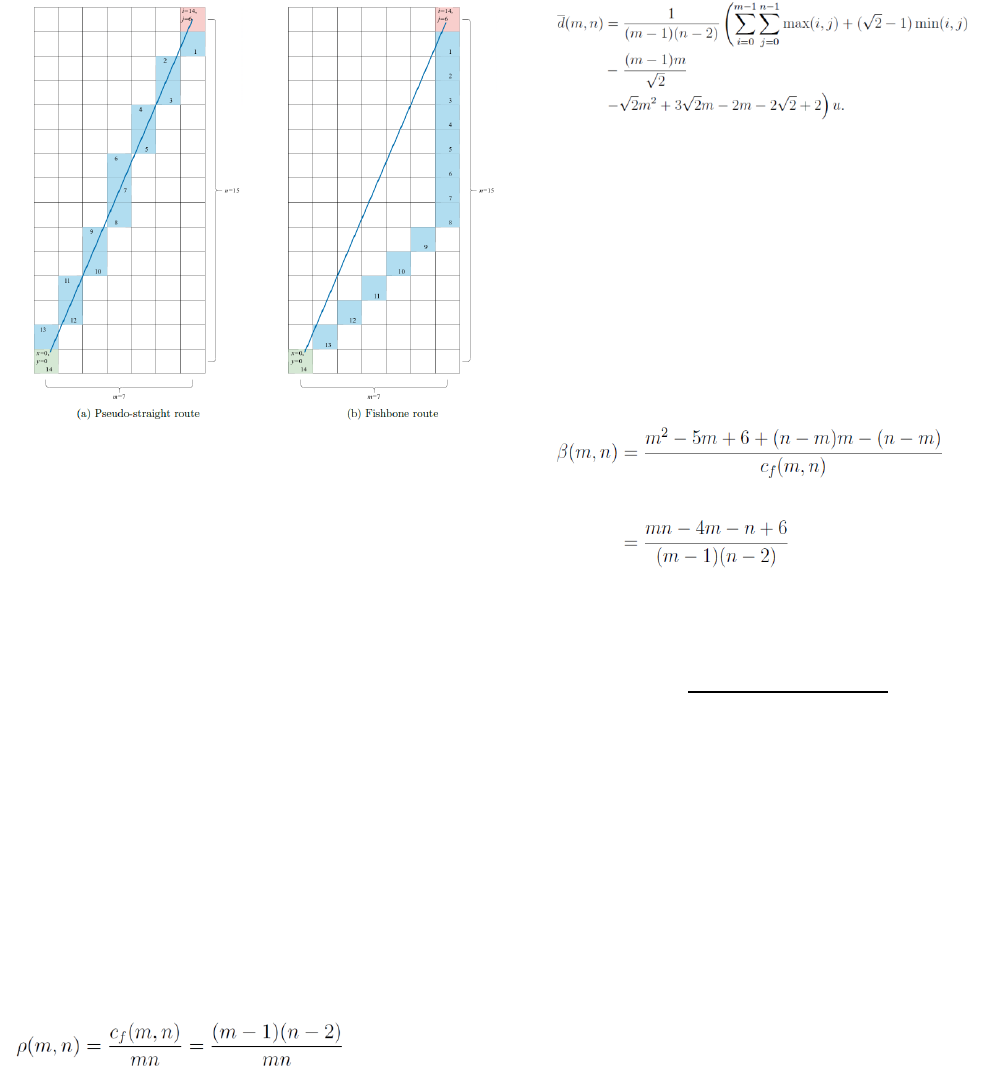

Regarding the movement policy, for any diagonal

movements, we can use a pseudo-straight route as the shortest

route since the route resembles the straight line between the cell

at (i, j) and the I/O-location and it can be modelled as sum of a

rectilinear movement and a diagonal movement in the square

sub-grid. It is easy to see from Figure 3 that, in fact, both routes

have equal route lengths. Moreover, the number of colored cells

is equal to the Chebyshev distance between the two cells.

Figure 3: Converting Psuedo-straight route to Fishbone route

In a generic grid, to move a load to I/O-location, in the

rectangular sub-grid, an empty aisle for the rectilinear

movement needs to be created (if the load is in a that sub-grid).

Then the load can be move to the side closest to the square sub-

grid where I/O is located. As soon as in the square sub-grid (or

if the load is already located in that sub-grid) there will be other

rectilinear movement (also in that case the empty aisle need to

be created) to enter the diagonal aisle of the square sub-grid and

then finally the diagonal movement to I/O-location.

Some movements can be synchronized, so the creation of

empty aisle and the movement of the load can be performed

sequentially or fully simultaneously.

Based on the assumptions and the movement policy

described here above, we developed some analytical models for

density, travel distance and travel time, considering different

configurations.

A. Density

Density for an m x n grid is modeled as the capacity divided

by the grid size. Grid size is the total number of cells in the grid,

while we need to leave an empty aisle for the diagonal of the

square sub-grid and an empty rectilinear aisle for the rectangular

sub-grid. So the density is expressed as (1):

(1)

B. Average travel distance

Average travel distance for an m x n grid is modeled based

on the potential diagonal movement as follows, where i and j are

the coordinates of the analysed cell and u is the length of the

sides of the cell in meters (in our study is 1m)

(2)

C. Average cycle time

The average cycle time needs to consider the time necessary

to create the empty aisle. In fact some loads need to wait for one

step for a rectilinear aisle to be opened before they can be

escorted to the IO-location. For these loads, this is the only

additional step beside the steps needed to transport the load to

the IO-location. The number of loads in the grid that require an

additional step to open a rectilinear aisle can be represented as a

fraction of all loads in the grid, β(m, n). The loads that require

an additional step are all the loads that are not next to the

diagonal aisle:

(3)

The average cycle time is so the additional time added to the

average travel time:

(4)

Where β(m, n)/v (we called βv) can be interpreted as the

average time used to move non-requested loads and d(m, n)/v

(we called dv) can be interpreted as the average travel time of

the requested loads.

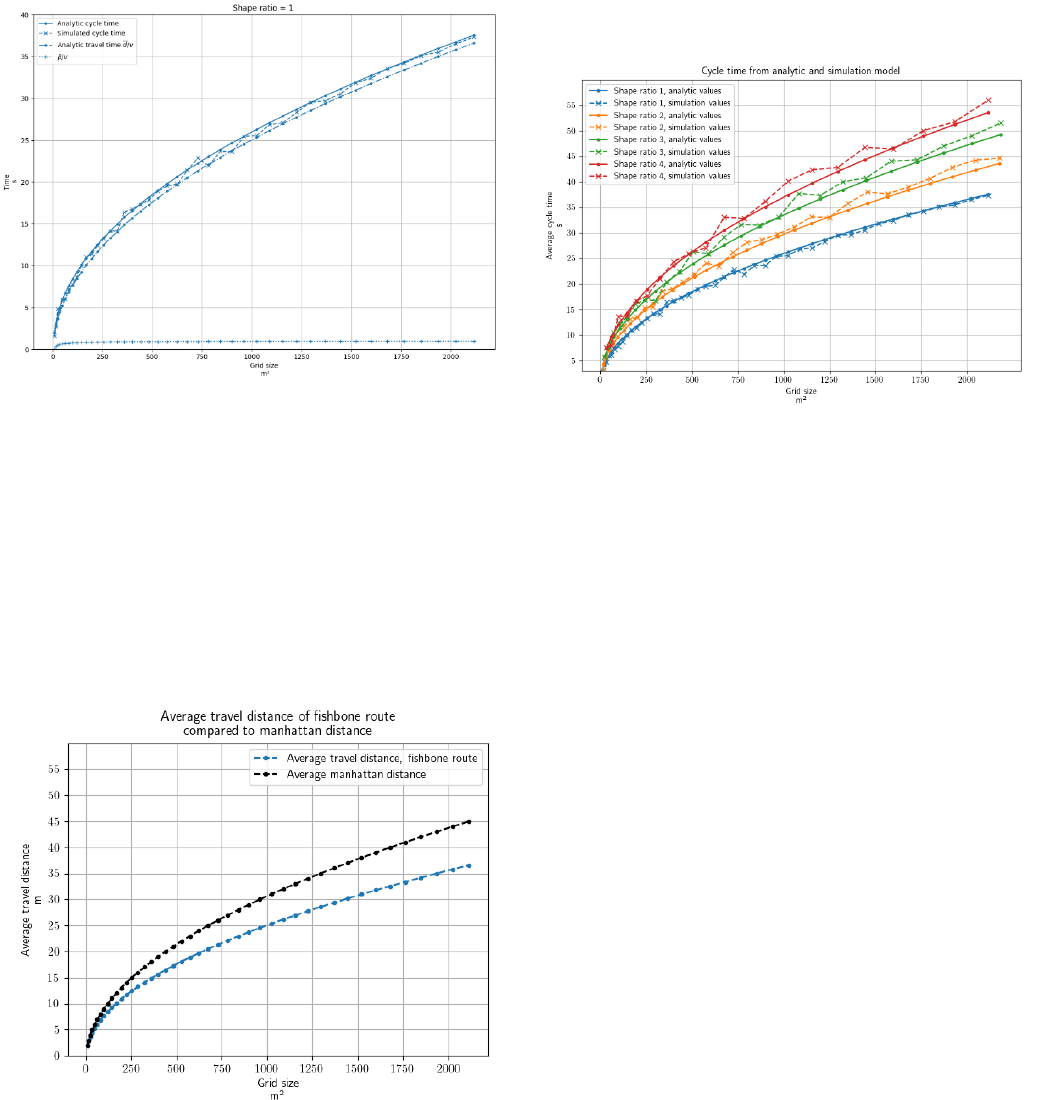

III. RESULTS AND DISCUSSION

We run different scenarios characterized by different

configurations. First with square shape and grid size from 0 to

2130 m². Then we considered rectangular shapes with different

ratio r = n/m, in particular 2, 3, and 4. We considered 1 I/O-

location as initial configuration and then we extended it to 2, 3

and 4.

First, we validated the analytical model with the results

obtained by the simulation for a shape ratio of 1. The accuracy

of the analytical model is promising with an error of about 2%.

We can see also that the additional time β is about 5% of total

time. Next, we can also observe that the average cycle time

follows a similar square root increase as the average travel

distance. The average cycle time can be decomposed into two

contributions, the time it takes for the requested load to travel

the average travel distance, the travel time, denoted dv, and the

extra time required to clear the way for the requested load,

denoted βv. Analytical and simulated average cycle time is

plotted together with analytical travel time dv and βv. Both βv

and average travel distance increase for increasing grid size, but

it is obvious how the extra time needed to open the rectilinear

(, ) =

((, ) +

(, ))

aisle is very small compared to the average travel time and

practically constant. For grids bigger than 225m², βv only ranges

between 0.86 seconds to 0.95 seconds, whereas average travel

time closely follows the same square root increase as the

analytical and simulated cycle time. Therefore, the average

cycle time is mostly dependent on the average travel time and

not the time of moving other loads.

Figure 4: Analytical model and simulation model for average cycle time.

Then we estimated the advantage to use diagonal movements

compared to traditional Manhattan ones in a squared grid (shape

ratio = 1) (fig. 5). The average Manhattan distance for a grid

with a size of 2116m2 is 45m, whereas the average travel

distance of our configuration and movement policy is 36.6m.

Overall, considering the different sizes, there is about 15% to

19% reduction in average travel distance compared to the

Manhattan distance. In general the average travel distance of the

fishbone route seems to follow a square root increase when the

grid size increase.

Figure 5: Average travel distance of Fishbone compared to Manhattan for shape

ratio = 1 – squared shape.

Average cycle times of four different shape ratios are

combined in in Figure 6. Possible configurations of m × r*n is

more sparsely distributed over grid sizes for increasing shape

ratio. This is why the number of points on each plots linearly

declines for increasing r. Average cycle time increases more

rapidly for larger shape ratios, with a simulated maximum of

37.34 seconds for the grid with r = 1 and a simulated maximum

of 55.99 seconds for the grid with r = 4 for the same grid size,

2116m². This is a 50.0% relative increase in average cycle time

from shape ratio r = 1 to r = 4.

Figure 6: Average cycle time for different shape ratios (both analytical and

simulation models)

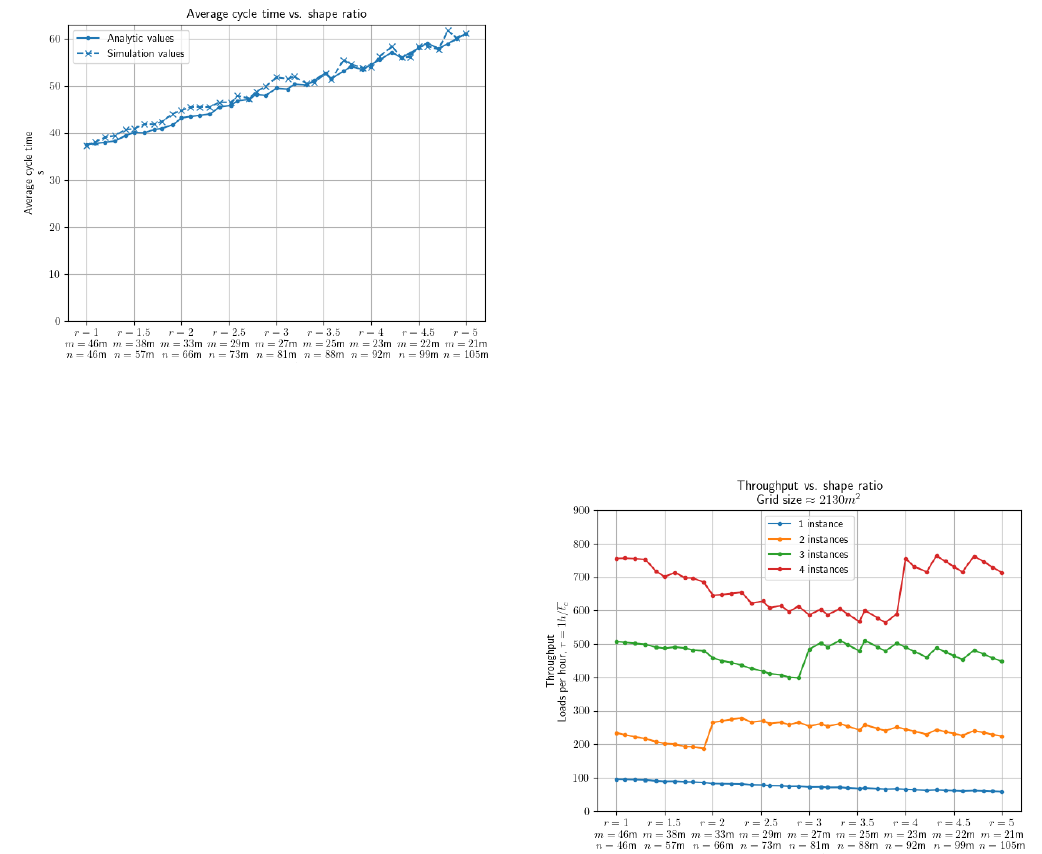

Change in average cycle time can be further investigated by

studying average cycle time for varying shape ratios. Figure 7

illustrates how average cycle time increases close to linearly

relative to the shape ratio. In this experiment, a fixed target grid

size is set to be 2130m², which was the maximum grid size of

the previous experiment. Since n and m must be integers, the

actual grid sizes deviate slightly for different size ratios, namely

SD=46,67 cells (= 2.14% relative standard deviation) for shape

ratios in the range 1 to 5. All grid sizes are within 4.74% of

2130m², yielding an average capacity of 2000 loads (SD=43,3

loads). The simulated average cycle time has a relative increase

of 63.7% from average cycle time of 37.34s when r = 1, to

average cycle time of 61.14s when r = 5. Again, by decomposing

the average cycle time, we can observe that the average travel

distance closely follows the average cycle time. The average

travel distance is 36.6m when r = 1, and 60.1m when r = 5.

However, the reduction in travel distance is only 3.1% compared

to the Manhattan distance when r = 5. This quick reduction in

improvement is because the angle of the diagonal aisle is always

45 degrees. Consequently, when the grid dimensions get more

skewed, travel along the diagonal aisle compared to rectilinear

aisles is lower, and the contribution of reduced travel distance is

less significant. Intuitively, when the grid dimensions get more

skewed, both the average Manhattan distance and the fishbone

route length get closer to the Euclidean distance because one

component of the travel route gets significantly longer than the

other. Nevertheless, to get the shortest average cycle time and

the biggest reduction in average travel distance compared to

Manhattan distance, grid dimensions should have a shape ratio

close to r = 1.

Figure 7: Average cycle time varying shape ratios (both analytical and

simulation models)

Number of I/O-locations has a great impact, but it depends

how square the total grid is and how many squared sub-grids can

be created based on the available I/O-locations

The analytical model has been used to estimate the

theoretical throughput of the grid configuration and movement

policy. In Figure 8 throughput for combinations of 1, 2, 3, and 4

I/O-locations is plotted for increasing shape ratio. This is the

inverse of the average cycle time from the last experiment

depicted in previous figures. The other grids have configurations

varying according to shape ratio as described in previous

sections. When a grid can consist only of I/O-location, the

maximum throughput is achieved when r = 1 with 95,9 loads per

hour. For grids consisting of 2, 3 and 4 I/O-locations, maximum

throughput is 274.8, 510.5, and 764 loads per hour at shape

ratios r = 2.2 r = 3.3 r = 4.3 respectively.

Naturally, throughput is higher for grids with more I/O-

locations, but the difference is not constant. Whereas throughput

of grids with a single I/O-location steadily declines for

increasing r, grids with combinations of instances experience

jumps in throughput for specific values of r. This behavior is a

consequence of how the I/O-locations are combined for different

grids and the effect of different shape ratios. With the specified

combination of grids, the throughput of the grids in this

experiment depends on two factors. The number of I/O-locations

is one obvious factor, but this is constant for increasing shape

ratio. The second factor is the average travel distance of each

individual instance in a grid, which does vary with the shape

ratio. For shape ratios greater or equal to the number of I/O-

locations, grids can suddenly be combined of I/O-locations with

individual shape ratios r = 1. As illustrated in the previous

scenario, grids with shape ratios closer to 1 have shorter average

travel distance and shorter average cycle time, thus increasing

throughput.

Moreover, before r is equal to the number of instances, a

relatively quick decline in throughput is noticeable for grids

consisting of 2, 3, and 4 I/O-locations compared to 1 I/O-

location. The relatively quick decline in throughput occurs

because the shape ratios of the individual I/O-location increase

more rapidly when the grid is divided into several I/O-locations

compared to one. This behavior stops when the shape ratio is

greater or equal to the number of I/O-locations in each grid,

where a less steep decline occurs.

Another pattern is noticeable when the shape ratio is greater

than the number of I/O-locations. Oscillations in throughput

occur in all grids for larger shape ratios. (This is easy to see from

Figure 8 for grids with 2, 3, or 4 I/O-locations, but also occurs

in grids with single I/O-locations as can be seen more easily in

Figure 7). Furthermore, the oscillations are larger for grids

consisting of more I/O-locations. The oscillations are also due

to variations in average travel distance for individual I/O-

locations, but more specifically, it is because the I/O-locations

must increase dimensions in incremental steps. In grids with

more I/O-locations, the effect is more drastic. The small spikes

occur whenever m is reduced by one. This pattern also occurs

when the shape ratio is less than four for grids consisting of four

I/O-locations. Since decrements in the shortest side occur more

frequently for smaller shape ratios, an oscillation occurs for

every change in shape ratio when 2.5 ≤ r ≤ 3.3.

Figure 8: Throughput vs shape ratio, varying the number of I/O-locations

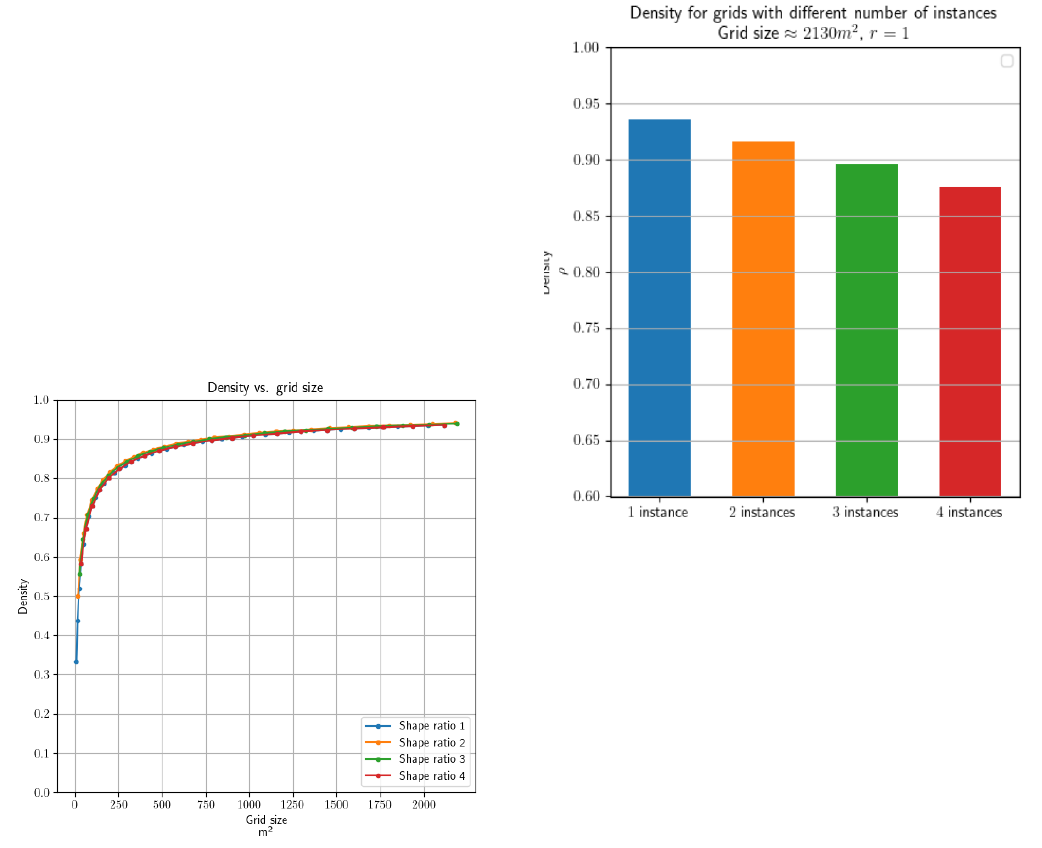

Densities for grids with different shape ratio all increase very

similarly with increasing grid size, as can be seen in Figure 5.5.

All grids reach a density over 0.9 when the grid size passes

841m² and reaches a maximal density of approximately 0.94 for

the maximal grid size.

Whereas the relative increase in average cycle time is 50.0%

for the biggest two grids with shape ratios 1 and 4, the density is

identical for both grids. The density for both grids with r = 1 and

r = 4 is 0.936 when the grid size is 2116m². Figure 9 shows how

densities in addition to being very similar for all shape ratios, are

practically identical for grids with shape ratio r = 1 and r = 4 for

all grid sizes. This similarity in density might seem

counterintuitive since a square grid requires escorts to make a

diagonal aisle, and a diagonal aisle requires more escorts than a

rectilinear aisle for aisles of the same length.

A grid with r = 4 needs mostly escorts to make a rectilinear

aisle, but a rectilinear aisle in this grid is relatively long

compared to the grid size. To be precise, the rectilinear aisle is

three times longer than the diagonal aisle when r = 4 and one

needs three escorts for every cell on the diagonal path to make a

diagonal aisle. Lastly, the diagonal path is twice as long for grids

with r = 1 compared to grids with r = 4. That is why the densities

are practically identical for grids with r = 1 and r = 4. Grids with

r = 2 and r = 3 achieve slightly higher densities but only a relative

increase of 0.4%.

To summarize, density is practically unaffected by shape

ratio, but shape ratio is a significant parameter for average travel

distance, and consequently, average cycle time.

Figure 9: Density vs grid size, varying the shape ratio

The previous scenario where a grid with a single I/O-location

is analyzed illustrates how density is practically independent of

shape ratio.

We can see how this is analogously transferrable to grids

consisting of multiple I/O-locations by observing how the

average density for grids consisting of 1, 2, 3 or 4 I/O-locations

is 0.938, 0.915,0.895, and 0.875 with minimal standard

deviations 0.002, 0.002, 0.005, and 0.006 respectively.

The difference in densities for the different number of I/O-

location in a grid occurs because each I/O-location needs an

independent set of escorts. The relative reduction in density is

only 6% from grids consisting of only one I/O-location to four

ones. Densities for grids consisting of the different number of

I/O-locations are plotted in Figure 10.

Figure 10: Density vs I/O-locations

IV. CONCLUSION AND FUTURE RESEARCH

Since Logistics 4.0 Lab (NTNU) started the collaboration

with wheel.me on the use of autonomous wheels in

intralogistics, the research team conceptualized a potential

application of the autonomous wheels to warehousing

applications.

By mounting autonomous wheels to an object, the object can

move independently and autonomously in any direction. So we

created a PBS system with movable racks, called Puzzle-Based

Movable Rack (PBMR) system, so reaching high density and

high throughput performance, even more exploiting the diagonal

movements.

We developed an analytical model for a modular

representation of the system, composed by square and

rectangular sub-grids, and we validated it with simulation.

We demonstrated the high density (around 90-95%) and

higher throughput compared to Manhattan movements (+ about

18%). We also investigated the implications of different

configurations, like varying the shape ratio and the number of

I/O-locations.

This is the first research investigating such system, so future

research is needed and they should focus first on the extension

of the analysis with more study on optimal design of such

system, considering also different storage policies. When design

guidelines have been introduced, research should focus on the

operational aspects of such system, studying for example the

sequencing of loads, the allocation of escorts, the allocation of

I/O-location. In both cases, design related and operational

related, multi-objective optimization or analysis should be

implemented in order to give practical implications to managers

when it comes to find the proper trade-off between density and

throughput.

Finally real testing and first implementation would be

needed to validate the results also in real operational conditions.

REFERENCES

[1] Boysen, N., De Koster, R., & Weidinger, F. (2019). Warehousing in the

e-commerce era: A survey. European Journal of Operational Research,

277(2), 396-411.

[2] Gue, K. R., & Kim, B. S. (2007). Puzzle‐based storage systems. Naval

Research Logistics (NRL), 54(5), 556-567

[3] Wurman, P. R., D'Andrea, R., & Mountz, M. (2008). Coordinating

hundreds of cooperative, autonomous vehicles in warehouses. AI

magazine, 29(1), 9-9.

[4] Azadeh, K., De Koster, R., & Roy, D. (2019). Robotized and automated

warehouse systems: Review and recent developments. Transportation

Science, 53(4), 917-945.

[5] Raviv, T., Bukchin, Y., & de Koster, R. B. M. (2023). Optimal Retrieval

in Puzzle-Based Storage Systems Using Automated Mobile Robots.

Transportation Science, 1-20.

[6] Gharehgozli, A., & Zaerpour, N. (2020). Robot scheduling for pod

retrieval in a robotic mobile fulfillment system. Transportation Research

Part E: Logistics and Transportation Review, 142, 102087.

[7] Keung, K. L., Lee, C. K., Ji, P., & Ng, K. K. (2020). Cloud-based cyber-

physical robotic mobile fulfillment systems: A case study of collision

avoidance. IEEE Access, 8, 89318-89336.

[8] Gue, K. R., & Meller, R. D. (2009). Aisle configurations for unit-load

warehouses. IIE transactions, 41(3), 171-182.

[9] Gue, K. R., Furmans, K., Seibold, Z., & Uludağ, O. (2013). GridStore: a

puzzle-based storage system with decentralized control. IEEE

Transactions on Automation Science and Engineering, 11(2), 429-438.

[10] Yu, Y., Yu, H., De Koster, R., & Zaerpour, N. (2017). Optimal algorithm

for minimizing retrieval time in puzzle based storage system with multiple

simultaneously movable empty cells. Working Paper Erasmus University,

Rotterdam.