This information does not constitute legal advice and is subject to change. Licensees are encouraged to seek legal

counsel to ensure their operations comply with the Medical Marihuana Facilities Licensing Act and associated

Administrative Rules.

SAMPLING AND TESTING TECHNICAL

GUIDANCE FOR MARIJUANA

PRODUCTS

Revised April 13, 2022

Supersedes March 8, 2022

Version 5.1

This information is intended for use by licensed safety compliance facilities and licensed

marihuana safety compliance facilities, collectively defined as laboratories, regulated by

the Cannabis Regulatory Agency (CRA).

This version of the technical guide combines and replaces all prior iterations published

under the purview of MMFLA, MRTMA, MTA and the Administrative Rules.

This information does not constitute legal advice and is subject to change. Licensees are encouraged to seek legal

counsel to ensure their operations comply with the Medical Marihuana Facilities Licensing Act and associated

Administrative Rules.

Contents

INTRODUCTION ........................................................................................................................................................ 1

REQUIRED SAFETY TESTS AND ACTION LIMITS .......................................................................................... 2

SAMPLING .................................................................................................................................................................. 2

ACTION LIMITS, LOQ’s AND MINIMUM TEST PORTIONS ........................................................................ 2

POTENCY ................................................................................................................................................................ 3

RESIDUAL SOLVENTS......................................................................................................................................... 3

Table 1. Action Limits for Residual Solvents. ...................................................... 3

HEAVY METALS .................................................................................................................................................... 4

Table 2. Heavy Metal Action Limits. ....................................................................... 4

FOREIGN MATTER ANALYSIS .......................................................................................................................... 4

Analysis for Organic Matter ....................................................................................... 5

Analysis for Inorganic Matter ................................................................................... 6

WATER ACTIVITY (a

w

) ........................................................................................................................................ 6

MICROBIALS .......................................................................................................................................................... 6

Table 3. Microbial Screening Action Limits (CFU/g). ......................................... 6

Table 4. List of Banned Chemical Ingredients: Action Limit and LOQ

[11]

. .. 7

TARGET ANALYTES ............................................................................................................................................ 8

Table 5. Target Analytes for Marihuana Products Intended for Inhalation. 8

MYCOTOXINS ........................................................................................................................................................ 8

Table 6. List of Required Mycotoxins and Accepted Detection Limits. ....... 9

HOMOGENEITY ..................................................................................................................................................... 9

pH ............................................................................................................................................................................ 10

Table 7. Marijuana Testing Requirements. ..........................................................11

RECOMMENDATIONS FOR QUALITY CONTROL .......................................................................................... 12

RECOMMENDATIONS ........................................................................................................................................ 12

Analytical Batch .................................................................................................................12

Laboratory Reagent Blank .................................................................................................12

ICV/CCV ............................................................................................................................12

This information does not constitute legal advice and is subject to change. Licensees are encouraged to seek legal

counsel to ensure their operations comply with the Medical Marihuana Facilities Licensing Act and associated

Administrative Rules.

Laboratory Fortified Matrix (LFM) / Laboratory Fortified Matrix Duplicate (LFMD) ..............12

Duplicate ............................................................................................................................13

ANNUAL REQUIREMENTS ............................................................................................................................... 13

Demonstration of Capability (DOC) ....................................................................................13

Method Detection Limit (MDL) ............................................................................................13

Corrective Action ................................................................................................................13

QC Acceptance ..................................................................................................................14

QC ACCEPTANCE CRITERIA* ............................................................................................................................. 14

DEFINITIONS ....................................................................................................................................................... 14

REFERENCES .......................................................................................................................................................... 17

1

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

INTRODUCTION

The Cannabis Regulatory Agency (CRA) is committed to evidence-based decision-

making when implementing technical guidance for licensed laboratories. As research

into marijuana use, safety, and testing advances, this guide may be revised and

updated to reflect these changes where appropriate. Upon licensing of a safety

compliance facility/marihuana safety compliance facility, licensees must comply with all

applicable statutes, administrative rules.

Rule (1) in the Marihuana Sampling and Testing Rule Set R 420.305 (1)

A laboratory shall become accredited for all required safety tests in at least 1 matrix to

the International Organization for Standardization (ISO), ISO/IEC 17025:2017, by an

International Laboratory Accreditation Cooperation (ILAC) recognized accreditation

body or by an entity approved by the agency within 1 year after the date the laboratory

license is issued and agree to have the inspections, reports, and all scope documents

sent to the agency.

Rule (2) in the Marihuana Sampling and Testing Rule Set R 420.305 (2)

A laboratory shall use analytical testing methodologies for the required safety tests in

subrule (3) of this rule that are based upon published peer-reviewed methods, have

been validated for cannabis testing by an independent third party, and have been

internally verified by the licensed laboratory according to Appendix J or K of Official

Methods of Analysis authored by the Association of Official Analytical Collaboration

(AOAC) International, with guidance from published cannabis standard method

performance requirements where available.

Rule (3) in the Marihuana Sampling and Testing Rule Set R 420.305 (3)

A laboratory must conduct the required safety tests specified in subdivisions (a) to (i) of

this subrule on marihuana product that is part of the harvest batch or production batch

as specified in R 420.303, except as provided in subrule (4) of this rule. The minimum

testing portions to be used in compliance testing must be consistent with the testing

portions used during method validation.

The sampling and analysis described in this guide must be conducted by a laboratory

licensed by the CRA and accredited to ISO/IEC 17025:2017 by an ILAC recognized

accreditation by 1 year after the date the license is issued. A laboratory must use

analytical testing methodologies that are based upon published, peer-reviewed methods

which have been validated for cannabis testing by an independent third party and have

been internally verified by the laboratory. Please refer to administrative rules for

additional guidance and clarification.

Analytical testing of marijuana for safety and potency is increasingly recognized as a

critical and necessary component of the industry for several reasons

[12]

: Moreover,

laboratory testing minimizes the risk of exposure to pesticides, microbes, heavy metals,

molds, and residual solvents by providing consumers with information about the

2

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

products they are purchasing and helps to prevent consumption by sensitive

populations.

Quantification of cannabinoid profiles and potency is available to the consumer to

inform decision making and aids in determining appropriate dosing for individual

use.

Laboratory testing provides transparency and promotes a sense of reassurance

to consumers as well as ensuring the quality of the marijuana product and that it

is safe for consumers.

REQUIRED SAFETY TESTS AND ACTION LIMITS

The CRA has established action limits for all required safety tests based on the most

current literature. The laboratory must report the results of the testing by indicating

“pass” or “fail” in the Metrc system and on the Certificate of Analysis (COA). The results

in the Metrc system and the COA should be identical aside from the reported results of

testing not required by the agency (i.e., terpenes). All results will be reported in parts

per million (ppm) and to 3 decimal places unless otherwise specified.

When reporting results for any analytes that were detected below the analytical

method Limit of quantitation (LOQ), include the numerical LOQ and indicate

“<LOQ” in the notes in the Metrc system.

All products should be tested “as is” with minimal manipulation to the sample

which could cause the results to no longer be representative of the product that

will go to the consumer.

SAMPLING

Rule (2) in the Marihuana Sampling and Testing Rule Set R 420.304 (3)

A laboratory shall collect samples of a marihuana product from another marihuana

business, and that marihuana business shall not interfere or prevent the laboratory from

complying with all of the following requirements: (n) The agency may publish guidance

that must be followed by marihuana businesses for chain of custody documentation.

The laboratory chain of custody must include the complete Metrc identification number,

name of product, type of product, number of containers, weight of both the source

package and test sample.

ACTION LIMITS, LOQ’s AND MINIMUM TEST PORTIONS

Rule (2) in the Marihuana Sampling and Testing Rule Set R 420.304 (3)

The agency shall publish a list of action limits for the required safety tests in subrule (3)

of this rule, except for potency. A marihuana sample with a value that exceeds the

published action limit is a failed sample. A marihuana sample that is at or below the

action limit is a passing sample.

3

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

POTENCY

Please refer to R. 420.305 (9) and R. 420.305(3)(a). Laboratories may analyze

additional cannabinoids with approval from the agency based on an acceptable method

validation and successful accreditation from ISO.

The laboratory must analyze a minimum 0.5 gram representative sample of marijuana

product to determine the cannabinoid profile. The laboratory must establish a limit of

quantitation (LOQ) of 1.0 mg/g or lower for all required cannabinoids analyzed and

reported.

RESIDUAL SOLVENTS

The laboratory must analyze a minimum 0.25 gram representative sample to assess the

presence of residual solvents in accordance with their associated action limits (Table 1).

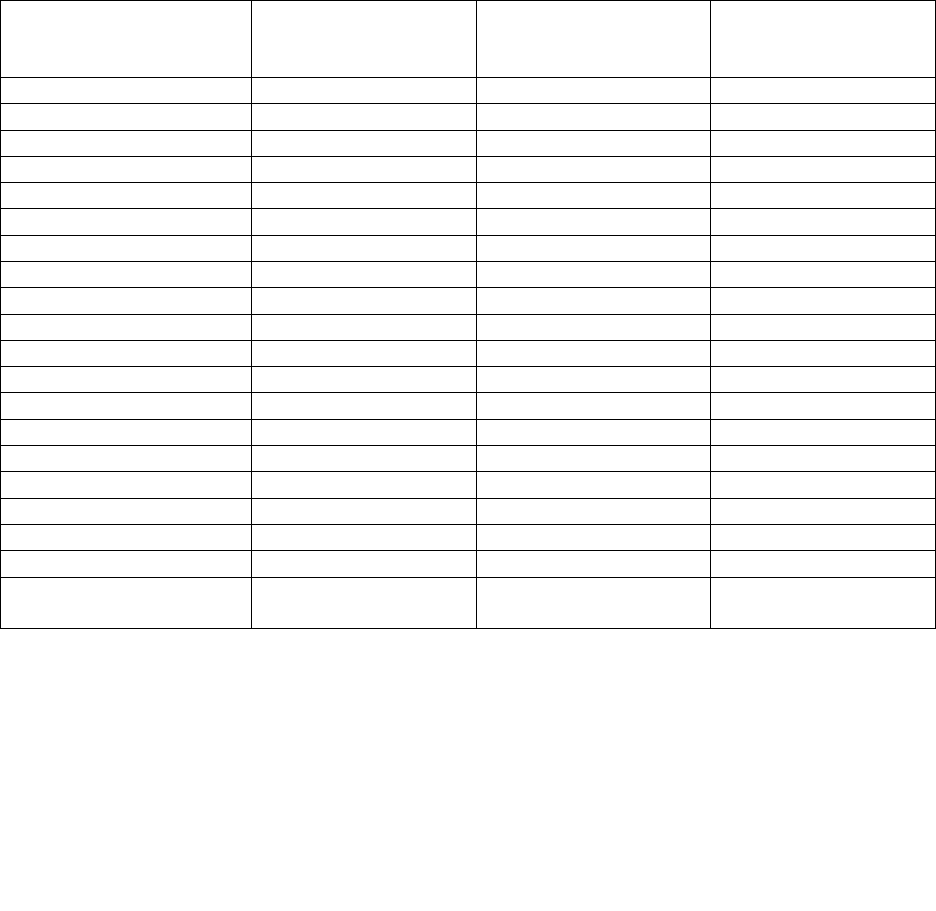

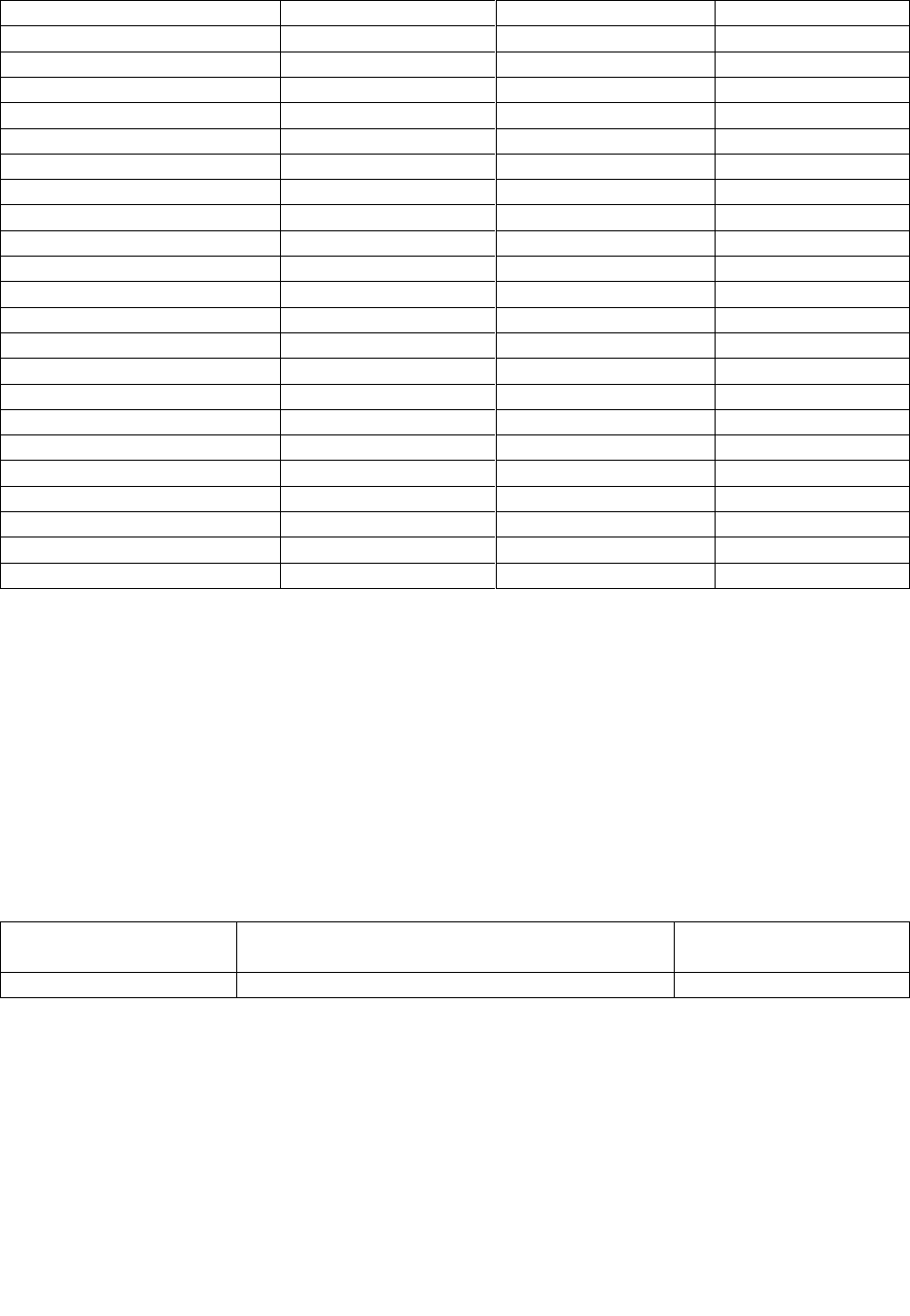

Table 1. Action Limits for Residual Solvents.

Solvent CAS Number Action Limit for

Inhaled Products

(ppm)

Action Limit for

Non-inhaled

Products (ppm)

1,2

-

Dichloroethane

107

-

06

-

2

2

.00

5

.00

Acetone 67-64-1 750 5000

Acetonitrile

75

-

05

-

8

60

.0

410

Benzene 71-43-2 1.00 2.00

Butanes all isomers*

106

-

97

-

8

800

5000

Chloroform

67

-

66

-

3

2

.00

60

.0

Ethanol 64-17-5 1000 5000

Ethyl acetate

141

-

78

-

6

400

5000

Ethyl ether 60-29-7 500 5000

Ethylene oxide

75

-

21

-

8

5

.00

50

.0

Heptane

142

-

82

-

5

500

5000

Hexanes all isomers^

110

-

54

-

3

50

290

Isopropyl alcohol

67

-

63

-

0

500

5000

Methanol 67-56-1 250 3000

Methylene chloride

75

-

09

-

2

125

600

Pentanes all isomers+ 109-66-0 750 5000

Propane

74

-

98

-

6

2100

5000

Trichloroethylene

79

-

01

-

6

25

.0

80

.0

Toluene 108-88-3 150 890

Total xylenes (ortho-,

meta

-

, para

-

)

1330-20-7 150 2170

* Butane isomers include 2-methylpropane or isobutane CAS Number 75-28-5.

+ Pentane isomers include isopentane (methylbutane) CAS Number: 78-78-4 & neopentane (dimethylpropane) CAS Number: 463-

82-1 Y

^ Hexane isomers 2,2-Dimethylbutane CAS Number: 75-83-2, 2,3-Dimethylbutane CAS Number: 79-29-8, 2-Methylpentane CAS

Number: 107-83-5, 3-Methylpentane CAS Number: 96-14-0

4

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

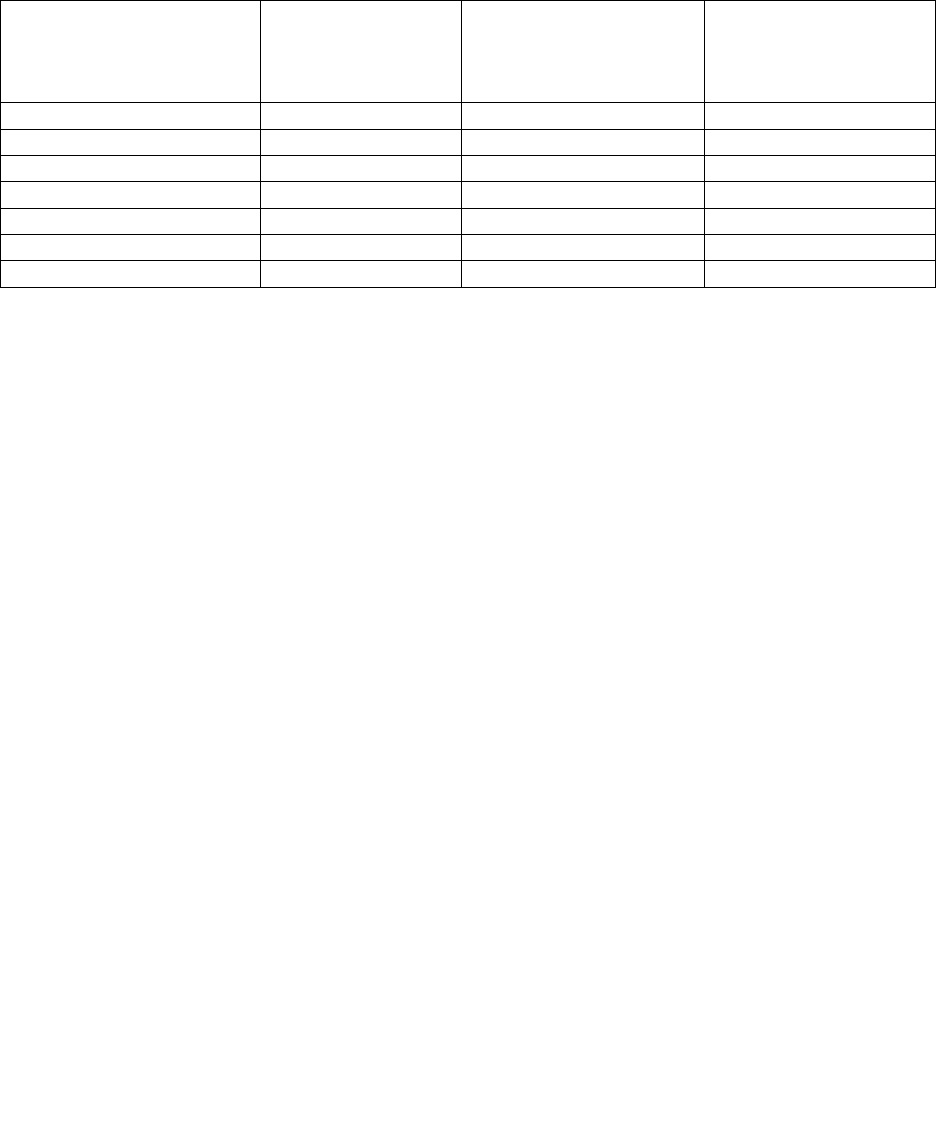

HEAVY METALS

The laboratory must analyze a minimum 0.5 gram representative sample of marijuana

products to assess the presence of heavy metals in accordance with their associated

action limits based on a 5 gram/day consumption of marijuana (Table 2).

The LOQ for heavy metals must be ½ the action limit.

Table 2. Heavy Metal Action Limits.

Heavy metal Action Limit for

Inhaled

Marijuana flower

(ppm)

Action Limit for

Inhaled Marijuana

concentrates (ppm)

Action Limit for

other Marijuana

products (ppm)

Lead

1.00 0.500 0.500

Inorganic Arsenic

0.4

00

0.2

00

1.5

00

Mercury

0.200 0.100 3.000

Cadmium

0.4

00

0.2

00

0.5

00

Total Chromium

1.2

00

0.6

00

2.0

00

Nickel*

1.0

00

0.5

00

N/A

Copper*

N/A

3.0

00

+

N/A

+ Copper is required for vaping products only.

FOREIGN MATTER ANALYSIS

The laboratory should perform foreign material testing on not less than 30% of the total

representative sample of intact buds and flower material prior to sample grinding or

milling.

1. The buds should be separated into no less than 10 increments. The results from

which can be averaged together as total foreign matter contamination.

2. Dissection of nodes should be done whenever physically possible.

3. If dissection of distinct nodes is deemed unnecessary, due to the small and compact

nature of the buds (“popcorn” buds), the buds then should be examined in their entirety

and additionally cut in half to observe the inside portion.

4. In the case of marijuana trim, kief, concentrate or infused product, the calculation to

determine 30% of the sampling batch should be included in the SOP.

5. Quantitation of filth should be done as a total surface area calculation. The

laboratory-derived calculation should be included in the SOP.

6. If a sample fails for foreign matter, the laboratory should include a note in Metrc

listing all contaminants identified.

When the laboratory performs foreign material testing, the laboratory must do all of the

following:

5

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

1. Develop a procedure and associated training documents for the identification of

powdery mildew, pests, mold and other foreign material which requires agency

approval before testing. The training document must include a reference text for

common cannabis contaminants.

2. Examine both the exterior and interior of the sample. Samples must be viewed

on both high and low power magnifications. Pests and other foreign

contaminants typically do not sit on the outside of the material and will require the

technician to dissect the material while viewing under a microscope.

3. All quantitation must be done on high power magnification and the laboratory

must develop a grading scale which clearly dictates a failed sample.

Example grading scale for pests:

0-2 pests per HPF(high power field) = mild

2-4 pests per HPF= moderate

4+ pests per HPF= severe

All samples graded as severe are automatic failures.

4. All failures should be documented photographically.

Analysis for Organic Matter

The action limit for crude marijuana is not more than 5.0% of stems and not more than

2.0% of other foreign matter. All failures should be documented photographically. It is

recommended that the laboratory clearly delineate calculation guidelines and ranges for

total surface area contamination. Foreign matter analysis should be performed prior to

all other testing, aside from microbials. The material remaining after foreign matter

analysis is acceptable for all chemical testing but should not be used for microbial

testing. The amount of marijuana or marijuana product used for testing should be no

less than 30% of the total gram weight or total sample lot obtained for compliance

testing.

In the case of marijuana flower, the allotted 30% should come from separate, intact

buds.

1. The buds should be separated into no less than 10 increments. The results

from which can be averaged together as total foreign matter contamination.

2. Dissection of nodes should be done whenever physically possible.

3. If dissection of distinct nodes is deemed unnecessary, due to the small and

compact nature of the buds (“popcorn” buds), the buds then should be examined

in their entirety and additionally cut in half to observe the inside portion.

4. In the case of marijuana trim, kief, concentrate or infused product, the

calculation to determine 30% of the sampling batch should be included in the

SOP.

5. Filth analysis should be performed at a low-power magnification.

6. Quantitation of filth should be done as a total surface area calculation. The

laboratory-derived calculation should be included in the SOP.

6

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

7. If a sample fails for foreign matter, the laboratory should include a note in

Metrc listing all contaminants identified.

Analysis for Inorganic Matter

For these purposes, inorganic matter includes, but is not limited to, any material that

would not normally be found on a living organism (plant) and includes materials such as

glass, metal shavings, or synthetic fibers. In this case, the presence of any inorganic

matter on any marijuana plant, concentrate, or infused product would result in an

automatic failure for foreign matter. The observed matter should be documented in the

results note included in Metrc.

WATER ACTIVITY (a

w

)

A marijuana sample passes water activity testing if the water activity does not

exceed 0.65 a

w

.

An edible marijuana-infused product passes water activity testing if the water

activity does not exceed 0.85 a

w

.

Non-edible marijuana-infused products are not subject to water activity testing.

Marijuana infused beverages are not subject to water activity testing with

approval from the agency.

MICROBIALS

Any detection that exceeds the published action limit is considered a failure based on

the criteria for acceptability (Table 3).

Table 3. Microbial Screening Action Limits (CFU/g).

Bud, shake/trim, and kief

from Harvest Batch

(CFU/g)

Marijuana-Infused Product (CFU/g)

Medical

Total Yeast & Mold

Count

10,000 10,000

Adult-Use

Total Yeast & Mold

Count

100,000 10,000

Total Coliform

1000 100

Shiga toxin-

producing E. coli

(STEC)

Not detected in 1 gram Not detected in 1 gram

Pathogenic

Salmonella spp.

Not detected in 1 gram Not detected in 1 gram

Aspergillus flavus,

fumigatus, niger &

terreus

Not detected in 1 gram Not detected in 1 gram

7

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

CHEMICAL RESIDUE

Rule 5(11) in the Marihuana Sampling and Testing Rule Set R 420.305 (11)

For chemical residue and target analyte testing, the agency shall publish a list of

quantification levels. Any result that exceeds the action limit is a failed sample.

The laboratory must analyze a minimum 0.5-gram representative sample for analysis of

chemical residues.

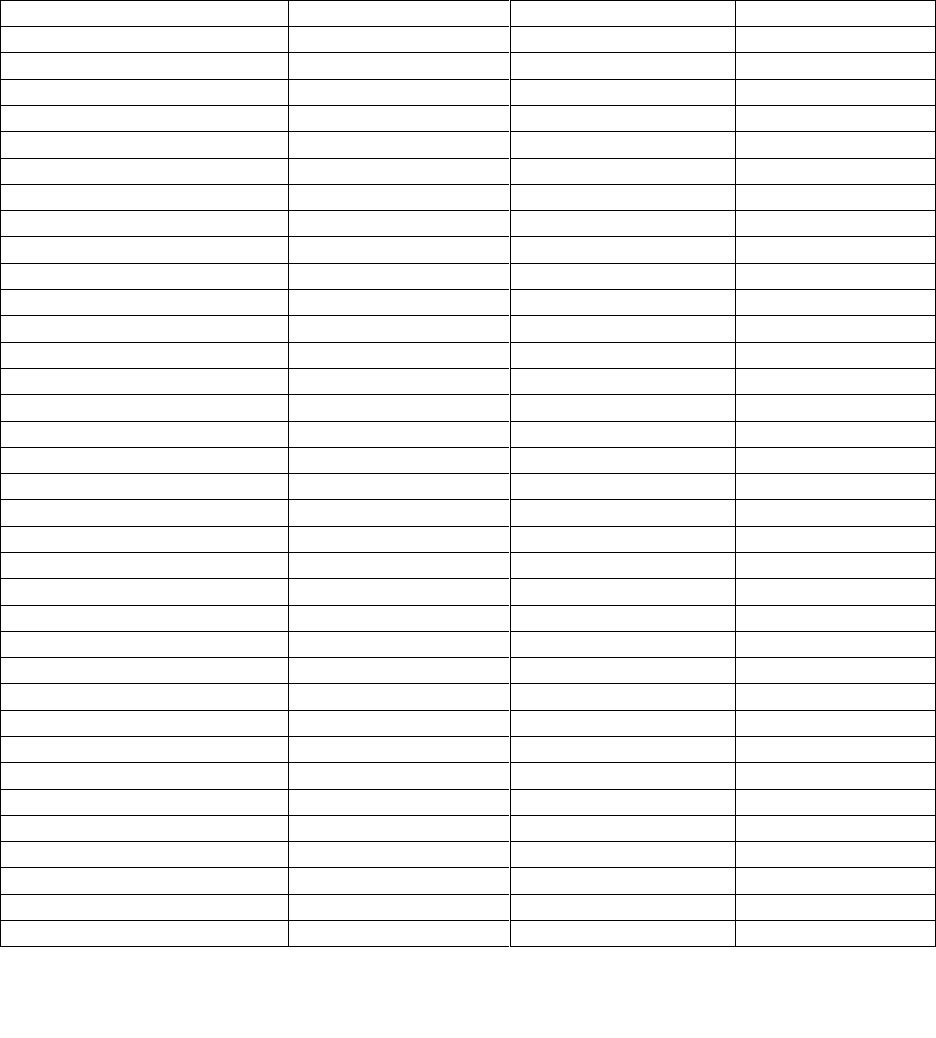

Table 4. List of Banned Chemical Ingredients: Action Limit and LOQ

[11]

.

Analytes

CAS Number

Action Limit (ppm)

LOQ (ppm)

Abamectin 71751-41-2 0.5 0.25

Acephate

30560

-

19

-

1

0.4

0.2

Acequinocyl 57960-19-7 2 1

Acetamiprid

135410

-

20

-

7

0.2

0.1

Aldicarb 116-06-3 0.4 0.2

Azoxystrobin

131860

-

33

-

8

0.2

0.1

Bifenazate

149877

-

41

-

8

0.2

0.1

Bifenthrin 82657-04-3 0.2 0.1

Boscalid

188425

-

85

-

6

0.4

0.2

Carbaryl 63-25-2 0.2 0.1

Carbofuran

1563

-

66

-

2

0.2

0.1

Chlorantraniliprole 500008-45-7 0.2 0.1

Chlorfenapyr

122453

-

73

-

0

1

0.5

Chlorpyrifos

2921

-

88

-

2

0.2

0.1

Clofentezine 74115-24-5 0.2 0.1

Cyfluthrin

68359

-

37

-

5

1

0.5

Cypermethrin 52315-07-8 1 0.5

Daminozide

1596

-

84

-

5

1

0.5

DDVP (Dichlorvos) 62-73-7 1 0.5

Diazinon

333

-

41

-

5

0.2

0.1

Dimethoate

60

-

51

-

5

0.2

0.1

Ethoprophos 13194-48-4 0.2 0.1

Etofenprox

80844

-

07

-

1

0.4

0.2

Etoxazole 153233-91-1 0.2 0.1

Fenoxycarb

72490

-

01

-

8

0.2

0.1

Fenpyroximate 134098-61-6 0.4 0.2

Fipronil

120068

-

37

-

3

0.4

0.2

Flonicamid

158062

-

67

-

0

1

0.5

Fludioxonil 131341-86-1 0.4 0.2

Hexythiazox

78587

-

05

-

0

1

0.5

Imazalil 35554-44-0 0.2 0.1

Imidacloprid

138261

-

41

-

3

0.4

0.2

Kresoxim-methyl 143390-89-0 0.4 0.2

Malathion

121

-

75

-

5

0.2

0.1

Metalaxyl

57837

-

19

-

1

0.2

0.1

8

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

Methiocarb 2032-65-7 0.2 0.1

Methomyl

16752

-

77

-

5

0.4

0.2

Methyl parathion 298-00-0 0.2 0.1

MGK

-

264

113

-

48

-

4

0.2

0.1

Myclobutanil 88671-89-0 0.2 0.1

Naled

300

-

76

-

5

0.5

0.25

Oxamyl

23135

-

22

-

0

1

0.5

Paclobutrazol 76738-62-0 0.4 0.2

Permethrins*

52645

-

53

-

1

0.2

0.1

Prallethrin 23031-36-9 0.2 0.1

Phosmet

732

-

11

-

6

0.2

0.1

Propiconazole 60207-90-1 0.4 0.2

Propoxur

114

-

26

-

1

0.2

0.1

Pyridaben

96489

-

71

-

3

0.2

0.1

Pyrethrins+ 8003-34-7 1 0.5

Spinosad

168316

-

95

-

8

0.2

0.1

Spiromesifen 283594-90-1 0.2 0.1

Spirotetramat

203313

-

25

-

1

0.2

0.1

Spiroxamine

118134

-

30

-

8

0.4

0.2

Tebuconazole

80443

-

41

-

0

0.4

0.2

Thiacloprid

111988

-

49

-

9

0.2

0.1

Thiamethoxam 153719-23-4 0.2 0.1

Trifloxystrobin

141517

-

21

-

7

0.2

0.1

* Permethrins should be measured as cumulative residue of cis- and trans-permethrin isomers (CAS numbers 54774-

45-7 and 51877-74-8).

+ Pyrethrins should be measured as the cumulative residues of pyrethrin 1, cinerin 1 and jasmolin 1 (CAS

numbers121-21-1, 25402-06-6, and 4466-14-2 respectively)

TARGET ANALYTES

“Target Analyte” is defined as non-marihuana inactive ingredient designated for

analysis.

Vitamin E Acetate has been identified as a target analyte by the CRA. All vape

cartridges must be tested for Vitamin E Acetate.

Table 5. Target Analytes for Marihuana Products Intended for Inhalation.

Target Analyte (CAS) Number

LOQ (ppm)

Vitamin E

Acetate

58

-

95

-

7

100

MYCOTOXINS

Rule (3) in the Marihuana Sampling and Testing Rule Set R 420.306 (3)

Products that failed testing for Aspergillus may be remediated after subsequent testing

for mycotoxins in accordance with R 420.305(3)(h).

9

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

The laboratory must analyze a minimum 0.5-gram representative sample for analysis of

mycotoxins.

Rule (20) in the Marihuana Sampling and Testing Rule Set R 420.305 (20)

The agency may request mycotoxin testing. A marihuana sample with a value that

exceeds the published acceptable level is a failed sample. A marihuana sample that is

below the acceptable value is a passing sample.

Table 6. List of Required Mycotoxins and Accepted Detection Limits.

Mycotoxin

PPB

Aflatoxin B1

<20

Aflatoxin B2

<20

Aflatoxin G1 <20

Aflatoxin G2

<20

Ochratoxin A <20

HOMOGENEITY

Homogeneity testing or the process of homogeneous sampling, is when all items in a

sample are chosen at random to be representative of product batch so they have similar

or identical traits. To perform homogeneity testing each dose or serving must be

treated as a separate individual sample and a total of 10 doses or servings must

be sampled at random. The weight and concentration of Delta-9 THC must be

recorded and the variability of weight and concentration of Delta-9 THC among servings

in a single package must not exceed +/- 15%.

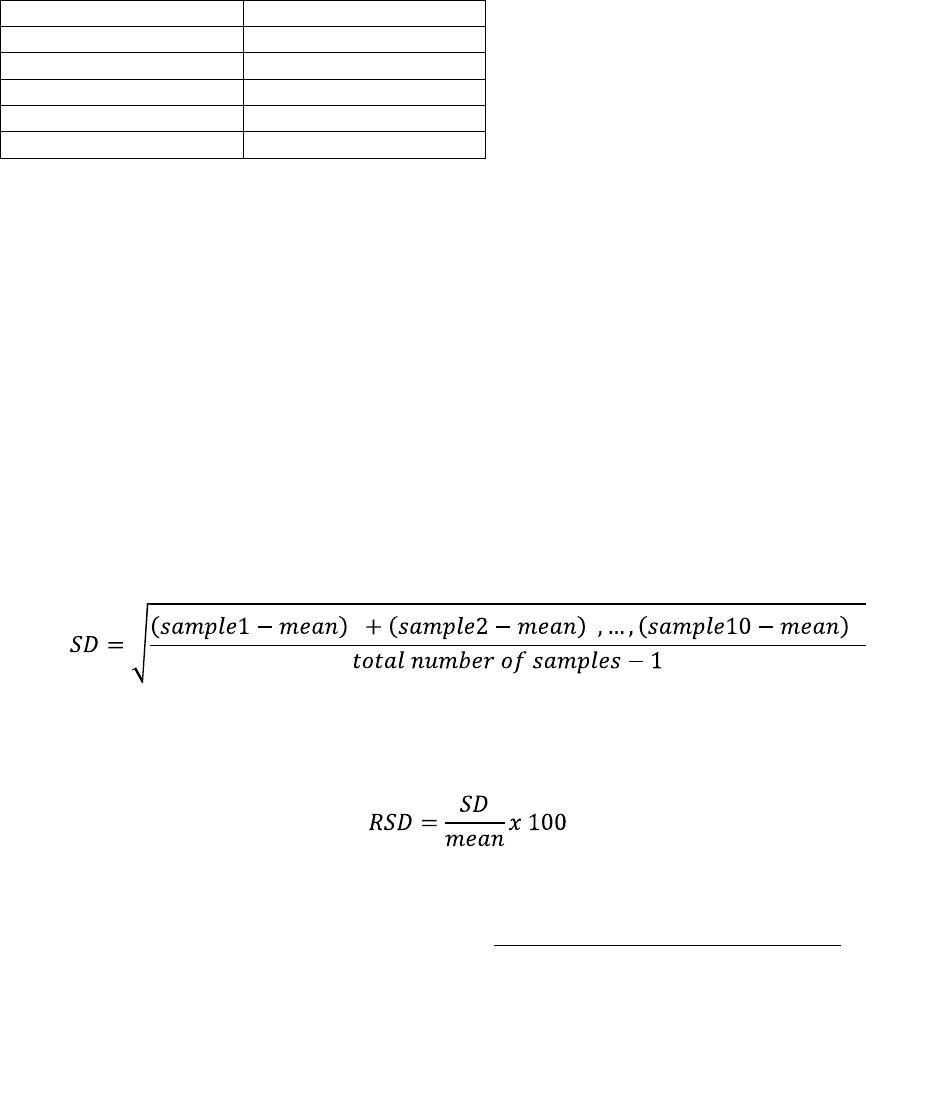

This can be determined by first calculating the Standard Deviation (SD) among samples

and subsequently calculating the Relative Standard Deviation (RSD) for both weight

and concentration of Delta-9 THC.

The SD is calculated using the following formula:

2 2 2

The RSD is calculated using the following formula:

The CRA has determined that the laboratories should complete potency testing based

on the information provided by the processors at the time of the sampling event. If a

product is sampled as an individual serving/dosage, the facility will report total THC by

10

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

serving/dose. If the product is sampled in final form, total THC content for the package

will be reported.

It is not incumbent on the laboratory to determine if the product will meet the package

labeling requirements. The laboratory testing results provided on the package will report

the calculated THC as the product was submitted for testing and is not required to

replicate the processor designated package label for THC content. The processor

designated package label will be considered the target THC.

pH

pH is a quantitative measure of the acidity or basicity of aqueous or other liquid solution

and is a required test for marijuana infused beverages. Any laboratory seeking approval

to test marijuana infused beverages must follow AOAC Method 945.10 and should

conduct analyses and validations in accordance with all manufacturer specifications.

11

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

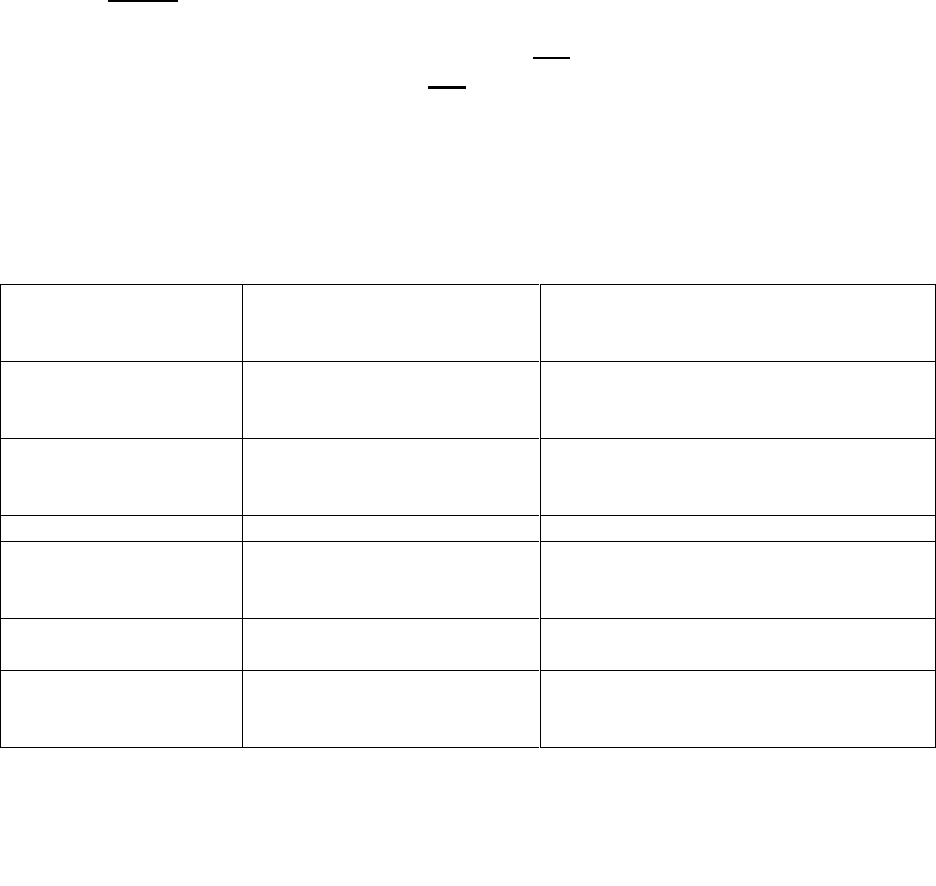

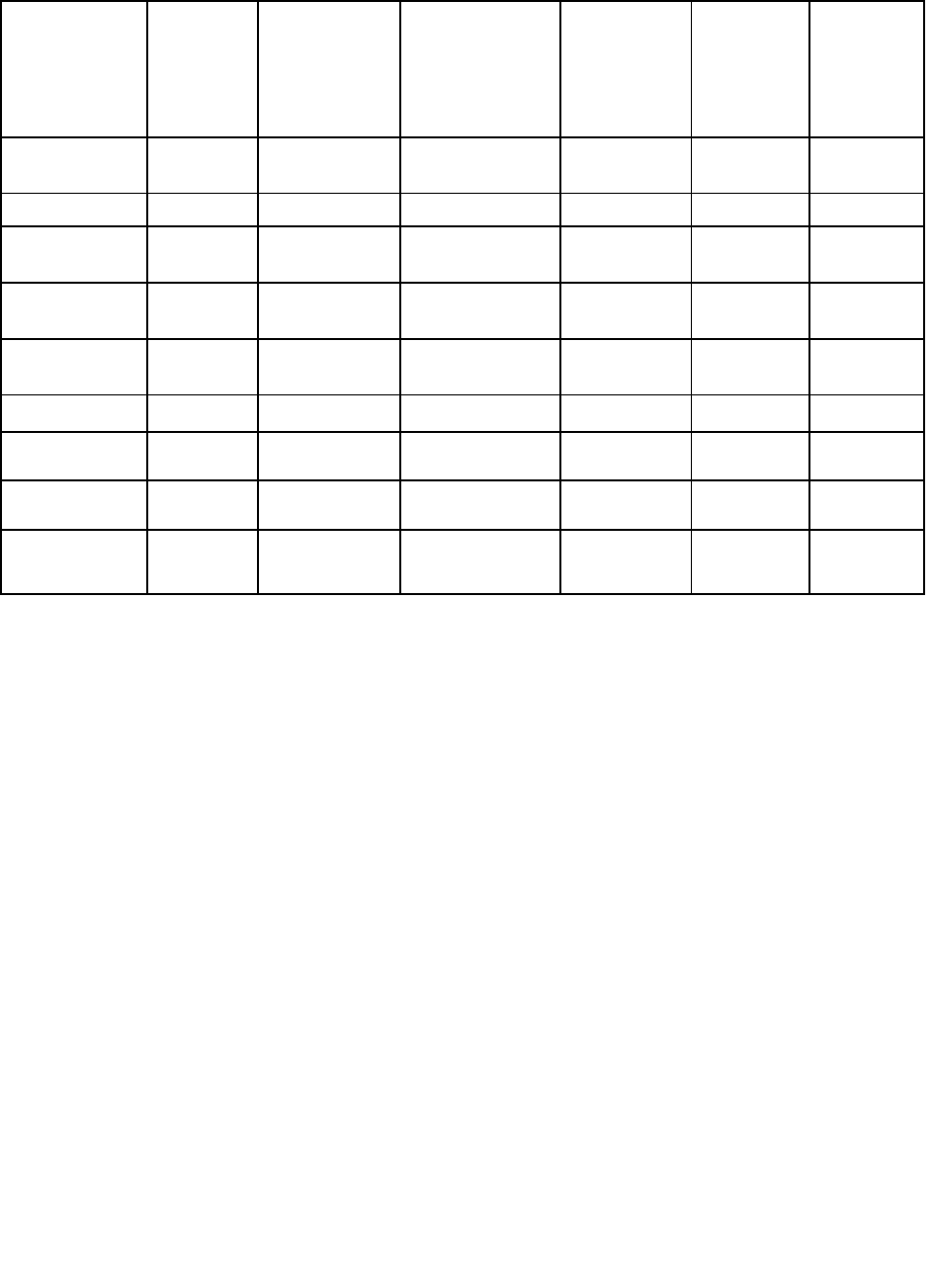

Table 7. Marijuana Testing Requirements.

a

Extraction using ice water, rosin press or dry ice

b

Not required for non-edible marijuana product or beverages with CRA approval.

c

Moonrock, Caviar joint, infused pre-roll, tarantula etc.

Raw Plant

Material

Non-Solvent

Concentrate

a

Inhalable

Concentrate

(Solvent based)

Vape

Concentrate

Inhalable

Compound

Concentrate

Products

c

Marijuana-

Infused

Product

Vitamin E

Acetate

√

Homogeneity √

Potency

Analysis

√ √ √ √ √ √

Foreign Matter

Inspection

√ √ √ √

Microbial

Screen

√ √

√ √

Water Activity √

√ √

b

Heavy Metal

Screen

√ √ √ √ √ √

Residual

Solvents

√ √ √ √

Chemical

Residue

Analysis

√ √ √ √ √ √

12

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

RECOMMENDATIONS FOR QUALITY CONTROL

Rule (5)(b) in the Marihuana Sampling and Testing Rule Set R 420.305b(5) A laboratory

must prepare a written description of its quality control activities, included as part of a

quality control manual.

All of the following items should be addressed in the quality control manual:

(a) Daily, weekly, monthly, and annual requirements.

(b) An analytical testing batch.

(c) All analytical testing runs must be bracketed with quality controls.

(6) Method specific quality control acceptance criteria, which must be followed.

RECOMMENDATIONS

Analytical Batch

Should be clearly defined as every 20 samples.

Laboratory Reagent Blank

Checks for background contamination should be the first sample of the analytical

run; a blank should also be run before and after a calibration check (CC), initial

calibration verification (ICV) /continuing calibration verification (CCV) and at the

end of the run.

ICV/CCV

Initial Calibration Verification (ICV) – the ICV is performed by analyzing a test

solution of known analyte concentration(s) after calibration, but before sample

testing on the initial day of the calibration. The ICV should be a standard that is

not from the same vendor/lot that is used for the calibration curve.

Continuing Calibration Verification (CCV) – the CCV is performed by analyzing a

test solution of known analyte concentration(s) prior to sample testing on each

testing day and continued periodically during the analytical batch run, no less

frequently than once after each set of 20 samples. The CCV should be a

standard that is not from the same vendor/lot that is used for the calibration curve

IF calibration is maintained for more than one week.

Laboratory Fortified Matrix (LFM) / Laboratory Fortified Matrix

Duplicate (LFMD)

Analyze a sample with a known amount of standard added (spike).

For the LFMD, spike the same sample a second time (duplicate).

13

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

Calculate Relative Percent Difference (RPD) between spiked sample and spiked

duplicate, target value should be close to the first value and have a small RPD

(less than 20%).

Spike volume should be less than 1% of the volume. Example: spike with 1 mL of

1000 mg/L into 100 mL sample will equal a 10 mg/L increase in concentration.

Duplicate

Analyze the same sample twice, this must be two separate preparations. The

sample should be chosen at random and run together on the same analytical run.

Calculate the relative percent difference (RPD) between first sample and

replicate, target value should be close to the first value and have a small RPD

(less than 20%).

Variability may be introduced during sample preparation. To account for this, if

more than one staff member is prepping samples, a sample duplicate for each

set of prepared samples must be run.

All validated approved methods have been demonstrated to be precise, therefore

laboratories are NOT permitted to run samples in duplicate and average the

results.

ANNUAL REQUIREMENTS

Demonstration of Capability (DOC)

Each analyst must have a DOC which includes documentation that they can

accurately run each test.

Documentation that an analyst has read and understands all appropriate SOPs

and methods.

Backup analysts should do this once a year or any time there is a reason to

question competence.

Competency assessments should be completed not less than annually including

having staff run a previously reported sample from sample preparation through

result reporting to assure all staff are following the written SOPs.

Method Detection Limit (MDL)

Run at least seven samples at low levels following procedure outlined below, i.e.,

daily requirements.

Corrective Action

Corrective actions must be included in the SOPs for each method and should

include what to do if QC tests fail or are out of range. For example, if standards

fail, then recalibrate and run test again.

14

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

QC Acceptance

Include in the SOP for each method the acceptance ranges for standards,

duplicates, spikes, etc., and verify that they match the method requirements.

QC ACCEPTANCE CRITERIA*

*unless otherwise specified in reference method.

LRB < MDL

ICV/CCV ± 10%

LFM/LFMD ± 20%

RPD < 20%

Reporting limit = MDL Calculations

% Recovery for LFB = LFB Result x 100%

Expected Concentration

RPD – relative percent differences for duplicates and LFM/LFMD

RPD = (|Num1-Num2| / ((Num1+Num2) / 2)) x 100

Where:

Num1= Original Number

Num2= Second Number

% Recovery for LFM – when using less than or equal to 1% spike volume compared to sample

volume

% Recovery = LFM Result – Sample Result X 100%

DEFINITIONS

A variety of definitions relating to detection limits and quantitation limits are published in

reference literature and by government agencies, however, universally accepted

procedures for calculating these limits do not exist. The definitions below attempt to

clarify the meaning of these terms as recognized by the CRA.

[13]

Analytical batch size: An analytical batch is defined as 20 samples excluding QC.

Calibration check (CC): Should be analyzed prior to sample analysis and every 10

– 20 samples thereafter (or after a 12-hour period, should less than 20 samples be

analyzed). The CCV controls are generally created from the same source as the

calibration material. The laboratory must outline acceptance criteria as relevant to the

method; ideally, the CCV should fall within at least ± 15% of the spike value.

15

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

Calibration requirements: Calibration must occur not less than monthly. At the

beginning of each day samples are to be analyzed, a calibration curve composed of four

or more points including all target analytes should be generated according to the

approved SOP. Where the determinative time is extensive and the instrument is stable,

the calibration curve should be initially developed; thereafter, each day that samples are

to be analyzed, this curve should be verified by analysis of a calibration check (CC)

following the requirements listed below. The check must be +/- 10% of the known value.

Continuing calibration verification (CCV): This verification should be done at

both the beginning and end of the analyses, including at least one standard for each of

the target analytes at the expected concentration range. It is recommended that a

calibration standard of one component of a multicomponent analyte also be analyzed

each day or work shift. All checks must be within 10% of the known value or the

instrument is to be recalibrated as specified in the calibration requirements.

Demonstration of capability (DOC): Each analyst should be assigned a file in

which records are maintained that demonstrate the capability of the individual to

perform analyses for which they are responsible on frequent or infrequent basis. At a

minimum, the analyst should calibrate and analyze four standards to demonstrate their

ability to run each test. Additionally, the file should contain documentation (signed form)

that the analyst has read and understands all assigned SOPs and methods. Backup

analysts should do this once a year. The primary analyst should recalculate DOCs when

a change in the method, analyst, or instrument is made which could affect precision,

accuracy, or sensitivity. Minor changes in methodology should prompt a check to verify

that the precision, accuracy, and sensitivity have been maintained.

Initial demonstration of capability (IDOC): Before beginning the analysis of

samples, an IDOC must be performed. The IDOC includes a demonstration of the ability

to achieve a low background, the precision and accuracy required by the method, and

determination of the limit of detection (LOD) (see below). An IDOC should be performed

for each instrument. It is also recommended that an IDOC be performed by each

analyst. In addition, it is recommended that the IDOC also addresses the variability

introduced if more than one sample preparation analyst is used. Precision, accuracy,

and LOD should be comparable for each technician.

Laboratory fortified sample matrix: Laboratory fortified sample matrix

requirements stated in the methods must be met. If there are no laboratory fortified

sample matrix requirements in the method, the following guidelines are to be used: The

laboratory should add a known quantity of analyte(s) to a percentage (to be described in

the approved SOP) of the routine samples to determine sample matrix interference; the

fortified concentration should not be less than the concentration of the sample selected

for fortification unless specified by the method; if the sample concentration is unknown

or less than detectable, the analyst should choose an appropriate concentration (e.g., a

percentage of the published action limit or mid-point in the calibration range); over time,

samples from all routine sources should be fortified; the procedure should be described

in the SOP; if any of these checks are not within the criteria specified in the method or

16

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

control limits specified in this document, and the laboratory performance is in control,

the result for that sample should be flagged to inform the data user that the results are

suspect due to matrix effects.

Laboratory reagent blank (LRB): An LRB should be carried through the full

analytical procedure with every sample batch. In general, results from LRBs should not

exceed the laboratory's minimum reporting limit (MRL), the lowest concentration of

standard used for quantitation.

Limit of detection (LOD) or detection limit:

The lowest concentration level that

can be determined to be statistically different from a blank (99% confidence). The LOD

is typically determined to be in the region where the signal to noise ratio is greater than

five. Limits of detection are matrix, method, and analyte specific. The LOD is

approximately equal to the MDL for those tests which the MDL can be calculated.

Limit of quantitation (LOQ): The minimum concentration or mass of an analyte in

a target matrix that can be reported as a quantitative result. For all analyses aside from

Target Analytes, the LOQ must be at a minimum 1/2 of the published action limit when

the LOQ is not specified in the SMPR. The analyst should determine LOQs when any

change is made which could affect the LOQs, or more frequently if required by the

method. In addition, the analyst must demonstrate low-level capability on an ongoing

basis through an LOQ determination or repeated low-level analyses.

Linear calibration range (LCR): The region of a calibration curve within which a

plot of the concentration versus the response of a particular analyte remains linear, and

the correlation coefficient of the line is approximately 1 (0.995 for most analytes). The

plot may be normal-normal, log-normal, or log-log when allowed by the analytical

method.

Low level quantitation: The laboratory's minimum reporting limits (MRL) should be

reported to the client along with the data. The reporting limit must be below the CRA’s

published action limits. Laboratories should run an LFB at their MRL every analysis day

and should not report contaminants at levels less than the level at which they routinely

analyze their lowest standard.

Method detection limit (MDL): The minimum concentration of a substance that

can be measured and reported with 99% confidence that the analyte concentration is

greater than zero and is determined from analysis of a sample in a target matrix

containing the analyte. The MDL procedure is designed to be a straightforward

technique for estimation of the detection limit for a broad variety of physical and

chemical methods. The procedure requires a complete, specific, and well-defined

analytical method. It is essential that all sample processing steps used by the laboratory

be included in the determination of the MDL. To calculate MDLs, please follow this

procedure.

17

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

REFERENCES

Aldous, K., Applen, J., Fan, Z., Fox, M., Kassner, S., Latshaw, M., & Verbrugge, D. (2016). Guidance for

State Medical Cannabis Testing Programs. Association of Public Health Laboratories.

[1]

AOAC. Official Methods of Analysis 991.14. 1994. Coliform and Escherichia coli counts in foods. AOAC.

Intl.

[2]

AOAC. Official Methods of Analysis 997.02. 2002. Yeast and mold counts in foods. AOAC. Intl.

[3]

ASTM D8196-18, Standard practice for determination of water activity (aw) in cannabis flower, ASTM

International, West Conshohocken, PA, 2018.

[4]

Audino, S., Acevedo, B., Angerhofer, M., Astill, T., Atkins, P., Aubin, A., & Brown, A. N. Standard Method

Performance Requirements (SMPRs®) 2018.011: Identification and quantitation of selected pesticide

residues in dried cannabis materials.

[5]

Audino, S., Angerhofer, M., Atkins, P., Brauninger, R. M., Brown, P. N., Burdette, C. Q., & Gibson, P.

(2017). AOAC SMPR® 2017.002. Journal of AOAC International, 100(4), 1204-1207.

[6]

Brabcová, I., Kovářová, L., Šatínský, D., Havlíková, L., & Solich, P. (2013). A fast HPLC method for

determination of vitamin E acetate in dietary supplements using monolithic column. Food analytical

methods, 6(2), 380-385.

[7]

Das, P., Kumar, S. R., & Maity, A. Risk based approach to evaluate the safety, risk and control of

Elemental Impurities in Pharmaceutical Drug Products

[8]

De Backer, B., Debrus, B., Lebrun, P., Theunis, L., Dubois, N., Decock, L., & Charlier, C. (2009).

Innovative development and validation of an HPLC/DAD method for the qualitative and quantitative

determination of major cannabinoids in cannabis plant material. Journal of Chromatography B, 877(32),

4115-4124.

[9]

EPA, U. (1995). Method 3052: microwave assisted acid digestion of siliceous and organically based

matrices. Test Methods for Evaluating Solid Waste.

[10]

Farrer, D. G. (2016). Technical Report: Oregon Health Authority's Process to Determine which Types of

Contaminants to test for in Cannabis Products, and Levels for Action. Oregon Health Authority, Public

Health Division.

[11]

Freeman, K., McHenry, M., Cats-Baril, W., & Grace, T. (2016). Cannabis Testing for Public Safety-Best

Practices for Vermont Analytical Laboratories. PhytoScience Institute.

[12]

Guidance, A. D. L. (1996). Laboratory Guide for Determining Method Detection Limits. Wisconsin

Department of Natural Resources Laboratory Certification Program April.

[13]

Guideline, I. H. T. (2005). Impurities: Guideline for residual solvents Q3C (R5). Current Step, 4, 1-25.

[14]

Guideline, I. H. (2018). Guideline for elemental impurities Q3D (R1).

[15]

International Conference on Harmonization. (2003). Q1A (R2), Stability testing of new drug substances

and products. In International Conference on Harmonization. Geneva: International Conference on

Harmonization.

[16]

Kagen, S. L., Kurup, V. P., Sohnle, P. G., & Fink, J. N. (1983). Marijuana smoking and fungal

sensitization. Journal of allergy and clinical immunology, 71(4), 389-393.

[17]

18

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

Kilmer, B., Caulkins, J. P., Midgette, G., Dahlkemper, L., MacCoun, R. J., & Liccardo, P. R. (2013). Before

the grand opening: Measuring Washington State’s marijuana market in the last year before legalized

commercial sales. Rand Corporation.

[18]

Kowalcyk, B., McLellan, M. R., Goldman, L., Goldman, D., Holmes, H. T., & Weaver, C. (2016). Office of

Regulatory Affairs Strategies for Building an Integrated National Laboratory Network for Food and Feed.

[19]

Lehotay, S. (2007). AOAC Official Method 2007.01 Pesticide residues in foods by acetonitrile extraction

and partitioning with magnesium sulfate. Journal of AOAC International, 90(2), 485-520.

[20]

Light, M. K., Orens, A., Lewandowski, B., & Pickton, T. (2015). Market size and demand for marijuana in

Colorado. Marijuana Policy Group.

[21]

Ma, C., Oketch-Rabah, H., Kim, N. C., Monagas, M., Bzhelyansky, A., Sarma, N., & Giancaspro, G.

(2018). Quality specifications for articles of botanical origin from the United States Pharmacopeia.

Phytomedicine, 45, 105-119.

[22]

McPartland, J. M., & McKernan, K. J. (2017). Contaminants of concern in cannabis: Microbes, heavy

metals and pesticides. In Cannabis sativa L.-Botany and Biotechnology (pp. 457-474). Springer, Cham.

[23]

Osterbauer, N., Krepps, S., Sackett, J., Holladay, C., Wendt, E., Wells, D., & Kristof, J. Protocol for

Collecting Samples of Usable Marijuana. ORELAP-SOP-001 Rev. 3.0. 2016 December.

[24]

Patel, B., Wene, D., & Fan, Z. T. (2017). Qualitative and quantitative measurement of cannabinoids in

cannabis using modified HPLC/DAD method. Journal of pharmaceutical and biomedical analysis, 146,

15-23.

[25]

Pharm, E., & Lipomed, A. G. (2017). AOAC SMPR® 2017.001.

[26]

Raber, J. C., Elzinga, S., & Kaplan, C. (2015). Understanding dabs: contamination concerns of cannabis

concentrates and cannabinoid transfer during the act of dabbing. The Journal of toxicological sciences,

40(6), 797-803.

[27]

Sexton, M., & Ziskind, J. (2013). Sampling cannabis for analytical purposes. BOTEC Analysis Corp, 26.

[28]

Thiex, N. J., & Ramsey, C. A. (2016). Taking and Testing GOODSamples: A Systematic Approach for

Representative Sampling from Field to Test Portion. Journal of Regulatory Science, 4(2), 1-8.

[29]

Thomas, R. (2018). Measuring Elemental Impurities in Pharmaceuticals: A Practical Guide. CRC Press.

[30]

Tchounwou, P. B., Yedjou, C. G., Patlolla, A. K., & Sutton, D. J. (2012). Heavy metal toxicity and the

environment. In Molecular, clinical and environmental toxicology (pp. 133-164). Springer, Basel.

[31]

Upton, R., & ElSohly, M. (Eds.). (2014). Cannabis Inflorescence: Cannabis spp.; Standards of Identity,

Analysis, and Quality Control. American Herbal Pharmacopoeia.

[32]

Unger, P., Brauninger, R., Hudalla, C., Holmes, M., & Sherman, B. (2014). Standards for Cannabis

Testing Laboratories. Eugene, OR: Cannabis Safety Institute. Retrieved, 4(01), 2016.

[33]

United States Pharmacopoeia. (2009). USP< 61> Microbiological examination of nonsterile products:

Microbial enumeration tests. In USP Pharmacists’ Pharmacopeia; United States Pharmacopeial

Convention: Rockville, MD: United States Pharmacopeial Convention. (p. S3).

[34]

19

This advisory bulletin does not constitute legal advice. Licensees should seek legal counsel to ensure their operations

comply with all applicable laws and administrative rules.

United States. Environmental Protection Agency. Office of Ground Water, & Drinking Water. Technical

Support Center. (1997). Manual for the Certification of Laboratories Analyzing Drinking Water: Criteria

and Procedures, Quality Assurance. US Environmental Protection Agency, Office of Water, Office of

Ground Water and Drinking Water, Technical Support Center.

[35]

United States Pharmacopoeia. (2009). USP< 62> Microbiological examination of non-sterile products:

tests for specified microorganisms. Rockville, MD: United States Pharmacopeial Convention.

[36]

United States Pharmacopoeia. (2012). USP< 467> Residual solvents. Rockville, MD: United States

Pharmacopeial Convention.

[37]

Voelker, R., & Holmes, M. (2015). Pesticide use on cannabis. Cannabis Safety Institute, 1-19.

[38]

Ziobro, G. C. (1996). Filth and extraneous materials in foods and drugs. Journal of AOAC International,

79(1), 252-253.

[39]